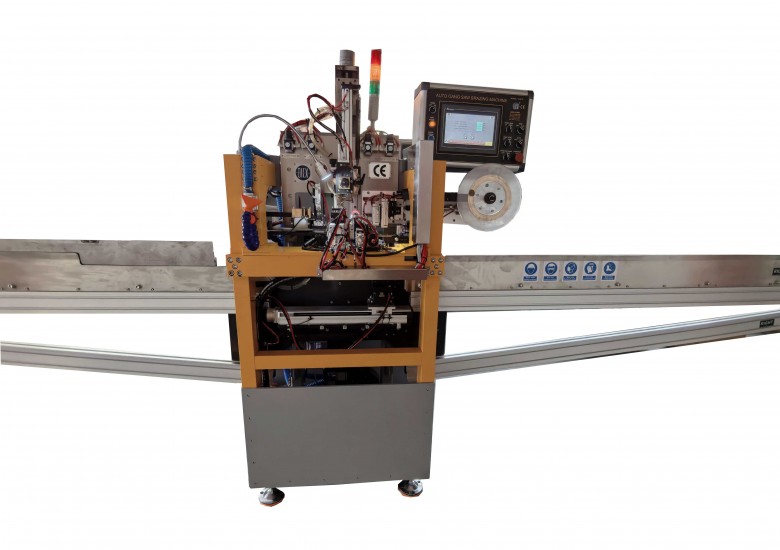

AUTO GANG SAW BRAZING MACHINE : GAB10

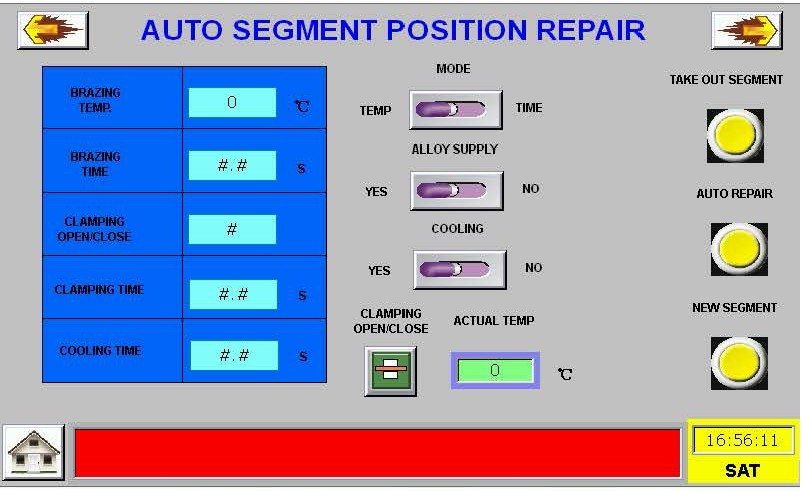

Seg repair option

AUTO GANGSAW BRAZING MACHINE : GAB10

AUTO GANGSAW BRAZING MACHINE for Zenesis segment :GAB10

Automatic induction brazing machine for diamond segments for gang-saw blade.

AUTO GANGSAW BRAZING MACHINE : GAB10

Option: Segment Take out function

Full Auto Brazing Position adjustment system for arrow shape shank brazing

MACHINE FEATURES

- Automatic feeding segments, transport,shank feeding of silver solder enable good quality of brazing.

- Fully automatic control by PLC & monitor program.

- High efficiency of brazing by H.F Induction generator.

- Every segment distance (pitch control)programed at Touch Screen.(36 program available)

- Heating by Time or Pyrometer as selection.

- Pitch control by Servo Motor+Ball Screw to endusre seg.distance.

- Auto segment position adjustent system via stepping motor and sensor for arrow shape gang saw.

TECHNICAL DATA

- MODEL NO. : GAB10

- POWER SUPPLY : 220/380V, 3PHASES, 50/60Hz

(Different voltages and frequencies on request)

- ELECTRIC POWER : 22 KVA

- COOLING WATER : 20 liter/min - 1~3 BARS

- AIR CONSUMPITION : 30 liter/min - 6 BARS

- Segment Length from 18 to 50 mm

- Segmetn Height from 5 to 25 mm

- Segment Thickness 1.5~12mm

- Segment No 1~34 or more

- Brazing Saw Size 2.1M~5.5M

- Program possible stored up to 36 programs

- OVERALL DIMENSIONS : L: 7,700Lx1,150Wx2,200 H mm

- WEIGHT(INDICATIVE) : Approx. 800 KG

- OPTION : Cooling system by Chiller / segment take out

Auto Segment Repair Function

For one segment or few segments repair or re positioning,we have delveloped new program to make one touch operation by

special program.

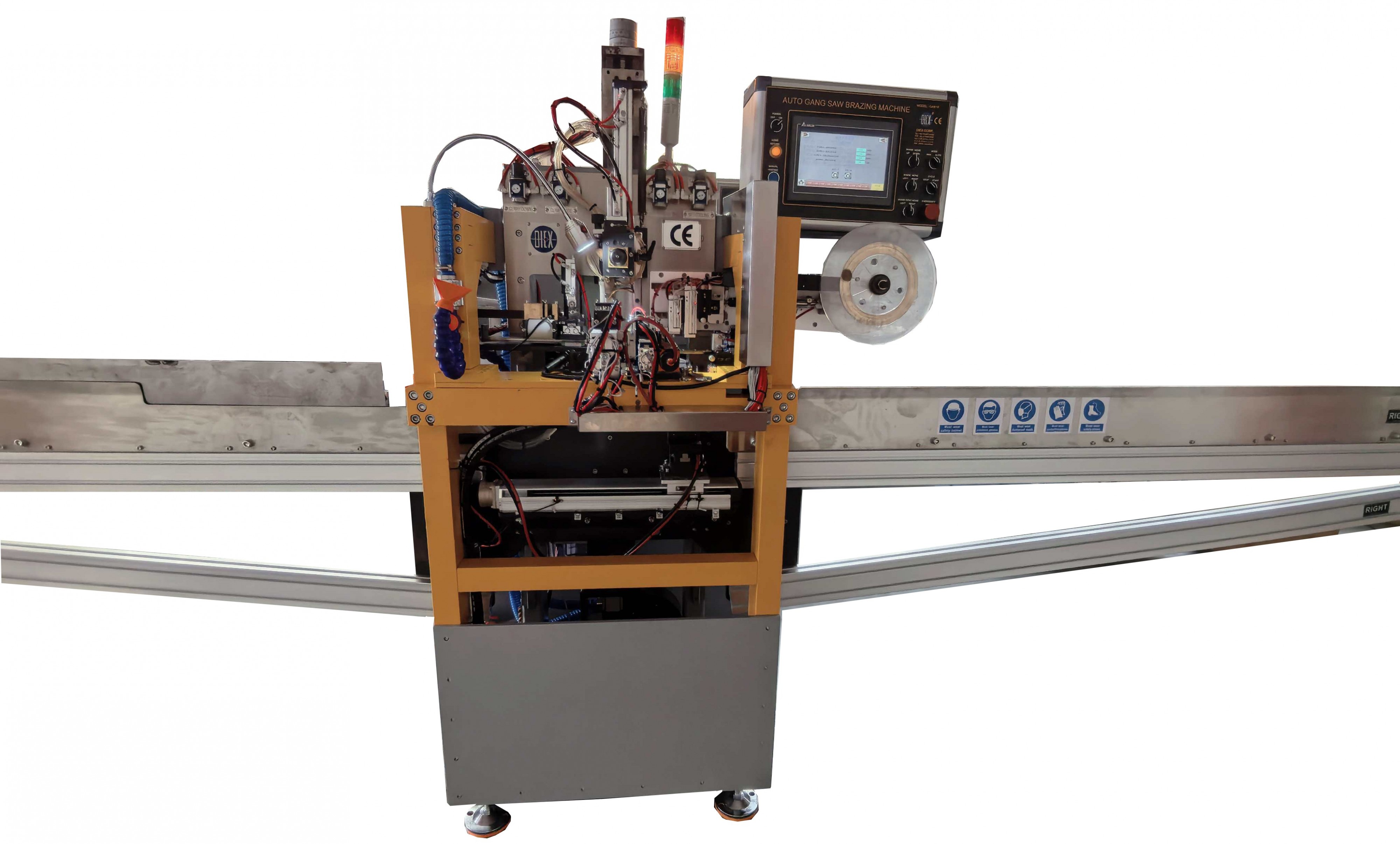

AUTO GANG SAW BRAZING MACHINE

( Special Version for Zenesis Segment )

* MAIN FEATURES

- Automatic feeding segments, transport,shank feeding of silver solder enable good quality of brazing.

- Fully automatic control by PLC & monitor program.

- High efficiency of brazing by H.F Induction generator.

- Every segment distance (pitch control)programmed at Touch Screen.(36 program available)

- Heating by Time or Pyrometer as selection.

- Pitch control by Servo Motor+Ball Screw to ensure seg.distance.

- Auto segment position adjustment system via stepping motor and sensor for arrow shape gang saw.

- Alloy precutting by pneumatic scissors & supply

- Auto Flux supply on segment & shank

-Special clamping jig system to allow to fix big ,tall segment in very stable condition

-Hydraulic clamping system with reinforced frame

* TECHNICAL DATA

- MODEL NO. : GAB10

- POWER SUPPLY : 220/380V, 3PHASES, 50/60Hz

(Different voltages and frequencies on request)

- ELECTRIC POWER : 22 KVA

- COOLING WATER : 20 liter/min - 1~3 BARS

- AIR CONSUMPITION : 30 liter/min - 6 BARS

- Segment Lengthfrom 18 to 50 mm

- Segmetn Height from 5 to 25 mm

- Segment Thickness1.5~12mm

- Segment No1~34 or more

- Brazing Saw Size2.1M~5.5M

- OVERALL DIMENSIONS : L: 7,700Lx1,150Wx2,200 H mm

- WEIGHT(INDICATIVE) : Approx. 1,000 KG

- OPTION : Cooling system by Chiller.

Segment Take Out function

1.Alloy cutting & supply by vacuum system

2.Auto Flux supply for segment & shank

3.Special clamping jig for big segment like Zenesis segments.

4.Hydraulic clamping system

5.Full Auto Brazing

6.Position adjustment system

NOTE

This technical data may be used only for guideline of production. DIEX Corp. will reserve the right to introduce any technical modification to its own machines, also in contract acquired, which its irrevocable decision are improvements. Therefore, any datum given on the catalogues & and data sheet has only indicative value.

Advanced Machines & Equipment for Diamond Tools

Advanced Machines & Equipment for Diamond Tools

DIEX CORP.

www.diex.com / sales@diex.com / T. +82 70-8877-4563 / F. +82 2-6442-3804