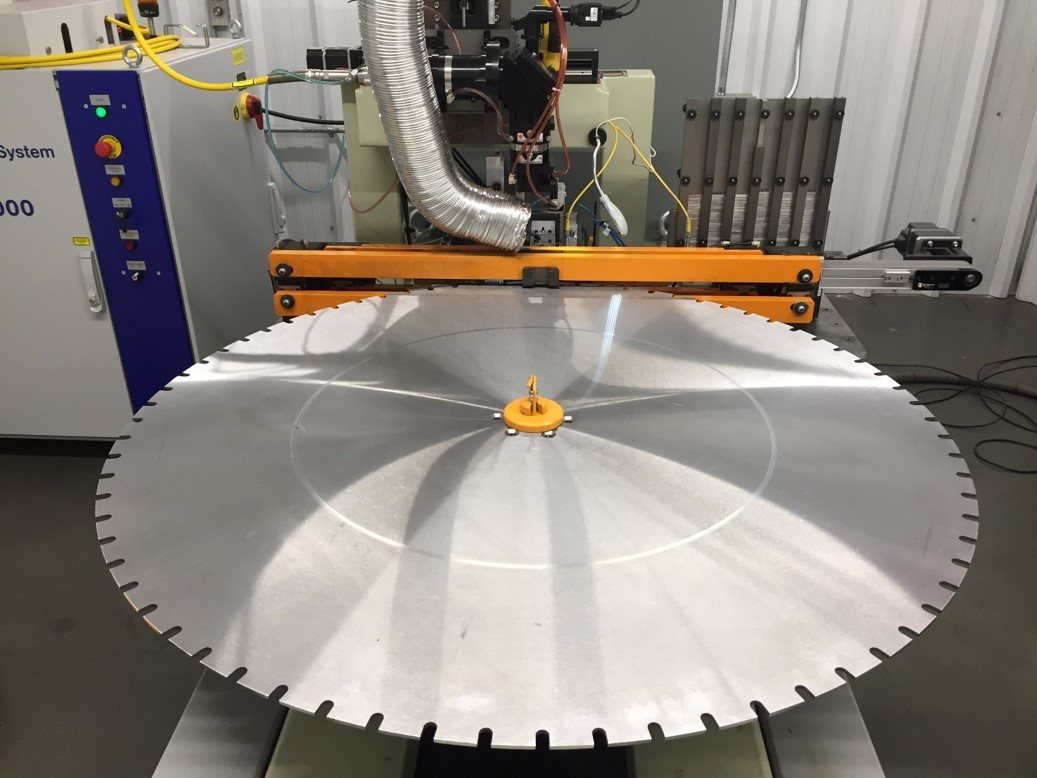

CNC Laser Welding Machine : CNC-L

CNC Laser Welding Machine NO. CNC-L

Fully CNC Control Laser Welding Machine using Fiber Laser Generator

MACHINE FEATURES

- The World Biggest Diameter Laser Welding Machine / Max. 1,855mm

- Auto loading & unloading up to max.dia. 600mm

- 700~1,855mm by Jib Crane loading & unloading

- Large Diameter CNC Controlled Laser Welding System Possible for big demolition & wall saw /Min. 105mm Max. 1,855 (73 inch)

- Segment Feeding (Option)

- Vertical Cartirige Magazine (approx. 300 segs)

- Bowl Feeding

TECHNICAL DATA

Fiber Laser Generator: 3.0 Kw – IPG Fiber Laser Generator

3.3Kw-Raycus Fiber Laser (Customer or Diex to supply )

Disk diameter range: 105-1855 mm / (105~1,200mm as OPTION with auto loading & Unloading)-Model:CNC-LA

Controller: CNC +PLC

Overall dimensions: 4200L x 2500Wx 2100mmH

Weight(Approx.) : 2,000kgs

NOTE

This technical data may be used only for guideline of production. DIEX Corp. will reserve the right to introduce any technical modification to its own machines, also in contract acquired, which its irrevocable decision are improvements. Therefore, any datum given on the catalogues & and data sheet has only indicative value.

Advanced Machines & Equipment for Diamond Tools

Advanced Machines & Equipment for Diamond Tools

DIEX CORP.

www.diex.com / sales@diex.com / T. +82 70-8877-4563 / F. +82 2-6442-3804